It was the early hours of a Monday morning when a sudden halt in production lines sent ripples of panic through the assembly floors. Machines, once humming in synchronized rhythm, now stood motionless. A single bottleneck had brought operations to a standstill, costing the company both time and money. What could have been avoided with proper planning? Manufacturing efficiency, or the lack thereof, can make or break a company in the competitive automotive parts industry.

For a company like SS396, known for its Chevelle, Nova, Camaro, and El Camino parts, manufacturing efficiency is not just a buzzword. It’s the backbone that ensures timely delivery of quality products, while also optimizing cost-efficiency. Whether you’re producing replacement parts for 1964-1977 Chevelles or restoring classic Camaros, manufacturing processes need to be finely tuned to ensure peak performance. So, how can manufacturers in this niche ensure that their operations run smoothly? Here’s a detailed guide on improving manufacturing efficiency, with actionable steps to help you stay ahead of the competition.

Understanding Manufacturing Efficiency

Manufacturing efficiency refers to the ratio of output to input in a production process. Simply put, it’s about getting the most out of the resources at hand – whether that’s time, labor, materials, or machinery. In the automotive parts industry, efficiency can mean reducing waste, cutting costs, and speeding up production timelines – all while maintaining product quality. The ultimate goal is to streamline operations and ensure that every component is produced with minimal waste, maximum output, and utmost precision.

The Importance of Manufacturing Efficiency in Automotive Parts

The automotive parts sector is a highly competitive industry, particularly when dealing with classic cars like the Chevelle or Nova. The demand for high-quality, reliable parts is constant, and customer expectations are high. Manufacturers need to balance speed with quality, all while managing a complex supply chain. Poor efficiency can lead to delays, increased operational costs, and lower quality products, which can harm a brand’s reputation.

Improving manufacturing efficiency isn’t just about boosting profits – it’s about staying competitive and delivering what customers expect. The better the efficiency, the quicker you can deliver products to market, the lower the costs, and the higher the overall quality of the end product.

Key Strategies to Improve Manufacturing Efficiency

1. Lean Manufacturing Principles

One of the most effective ways to improve efficiency in automotive parts manufacturing is through lean manufacturing principles. Lean manufacturing focuses on minimizing waste while maximizing productivity. This involves identifying and eliminating wasteful practices in your production process, such as:

- Excessive inventory: Overordering parts and materials ties up capital and increases the risk of materials becoming obsolete.

- Defective products: Rework due to defects not only costs money but also delays the manufacturing timeline.

- Unnecessary movement: Whether it’s staff walking too far or machines working inefficiently, reducing unnecessary movement speeds up the process.

Implementing a lean system means regularly assessing your production lines to identify waste and take corrective action. For example, Kanban boards can help manage inventory levels, and process mapping can highlight inefficiencies in production flows.

2. Embrace Automation and Technology

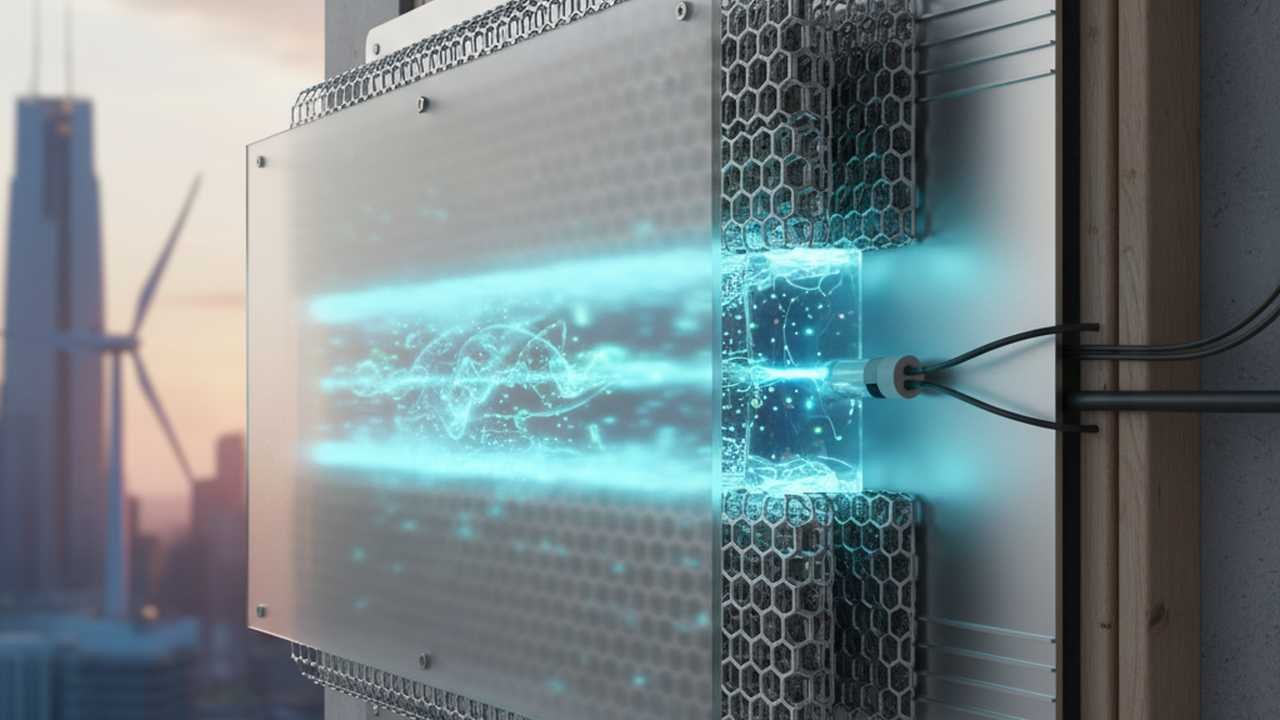

Incorporating automation is a game-changer for improving manufacturing efficiency. By automating repetitive tasks, you can reduce human error, increase speed, and lower labor costs. Technology like robotics and automated assembly lines can be particularly useful for tasks like welding, cutting, and assembly.

Advanced technologies such as Industrial Internet of Things (IIoT) can also play a crucial role. IIoT connects machines and systems in real-time, allowing manufacturers to monitor machine performance and identify potential issues before they become critical. Predictive maintenance, powered by IIoT, helps prevent costly downtime by alerting you when machines need maintenance or are at risk of failing.

3. Implement Just-In-Time (JIT) Inventory Management

JIT inventory management aims to minimize inventory levels while ensuring that materials are available when needed. Instead of overstocking parts and materials, you only order what’s required for production. This strategy reduces the costs associated with holding excess inventory, lowers waste, and allows you to focus on delivering high-quality parts on demand.

For example, if you’re manufacturing replacement panels for a 1970 Chevelle, you’ll want to make sure the materials for these parts arrive exactly when needed – no earlier, no later. JIT not only saves costs but also keeps production moving efficiently, preventing bottlenecks.

4. Streamline Your Production Process

Every step of your production process should be optimized for speed and efficiency. This includes everything from raw material procurement to the final packaging of parts. Start by analyzing each step in your process and ask yourself: “How can this be done faster or more effectively?”

For example, implementing workstations that are specifically designed for each task can speed up production. Also, creating standardized procedures for each task can help avoid delays caused by confusion or inconsistent work practices.

5. Train Your Workforce Continuously

Your workforce plays a critical role in improving manufacturing efficiency. Ensure that your employees are trained in lean principles, new technologies, and best practices. Regular training ensures that everyone is aligned with your goals and knows exactly what is expected of them in terms of quality and productivity.

Additionally, encourage an environment where employees feel comfortable providing feedback and suggesting improvements. Workers often have the best insight into how processes can be optimized, so it’s important to value their input.

Common Mistakes to Avoid

- Neglecting to invest in employee training.

- Overlooking the importance of regular equipment maintenance.

- Ignoring feedback from the production floor.

- Failing to adapt quickly to changing market demands.

Who Should Avoid This? Potential Drawbacks

While these efficiency improvements are beneficial for most manufacturers, there are some situations where they may not be suitable. Companies that are in the early stages of development or lack the financial resources to invest in automation or lean systems may face difficulties implementing these strategies effectively. Moreover, very small operations may not have the volume of products to justify certain high-tech investments, such as robotics.

Conclusion

Improving manufacturing efficiency is essential for any company in the automotive parts sector. By implementing lean principles, embracing automation, optimizing inventory management, and streamlining production, manufacturers can reduce costs, speed up production, and increase overall output. Continuous employee training and feedback also play a vital role in maintaining long-term efficiency.

For companies like SS396, improving manufacturing efficiency is an ongoing process that requires commitment, strategy, and the willingness to adapt. By focusing on these areas, you’ll not only increase profitability but also establish a reputation for delivering high-quality automotive parts quickly and efficiently.